PVC/PET cylinder box machine

high frequency weld machine

other plastic boxes machine

How to choose right plastic welding machine

Three kinds of plastic welding machine for choose

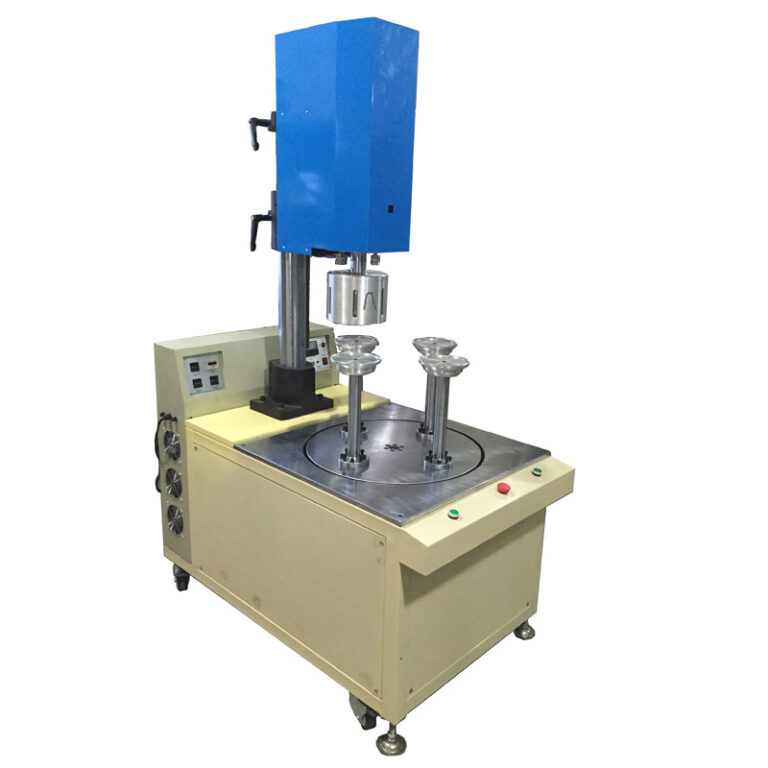

1)ultrasonic plastic welding machine

Advantage: good for PVC,PP,ABS,APET,PETG…many kinds of plastic welding.

Disadvantage: good for small size plastic welding. (also called spot welding)

2)high frequency pvc plastic welding machine

- Advantage: melt two piece pvc compound sheet and press to be one piece which never separated in the future

- Disadvantage: only good for pvc or pvc compound material welding (such as pvc blister package, pvc tarpaulin…) For PET material, it is suitable to sealing oft crease lines to make clear package box

3)heat plate blister paper card sealing machine

- Advantage: Good for all kind of plastic blister+coated paper card sealing for package, big size sealing

- Disadvantage: welding paper need to coated with sealing plastic sealing oil

Choose the suitable machine by

- 1)material of your products like( PVC, PET,PETG,GAG,APET,ABS,PP…)

- 2)design shape of welding products.(sheets or with special design shape)

- 3) welding areas of products( big size welding or spot welding)

——More technology suppoer about JCwelder Plastic tube box making machines—————————————–

- working manual of pvc tube boxes machine part 1-application&features&specifications

- Why and why not fully automatic PVC clear tube packaging box machine

- clear acetate tube machine Introduction JC-180S

- How to operate clear PVC cylinder boxes machine, model JC-180S

- Working principle of acetate cylinder packaging machine JC-180S

- Applications of HR welder

- Seal Types and Welding Seams

- How to choose the suitable welding RF machine

- Names of Radio Frequency Welding Machine

- How to make a perfect welding result

7002.png)