other plastic boxes machine

high frequency pvc weld machine introduction

s-1-1024x410.jpg)

High frequency refers to electromagnetic wave frequencies that are higher than other specific frequency ranges, usually between MHz and GHz.

High frequency welding (known as Radio Frequency (RF) ,HF welding or Dielectric welding ) is a manufacturing process where two plastic parts are welded together using an electromagnetic field. The resulting join can be very strong – often close to the original strength of the materials joined.

RF welding stands for Radio Frequency Welding, which is energy that is created by the RF equipment to weld specific types of thermoplastics. RF excites the molecular structure of the material causing it to heat very rapidly. Once heated, an RF die forced into the material by a press, determines the final shape and characteristics of the finished sealed product.

High frequency welding machine is a device that uses  high frequency welding technology to firmly fuse two or more layers of plastic together.Usually, high frequency welding machine manufacturers will design and make many RF plastic welder with different appearances according to the specific needs of customers.

high frequency welding technology to firmly fuse two or more layers of plastic together.Usually, high frequency welding machine manufacturers will design and make many RF plastic welder with different appearances according to the specific needs of customers.

The material most common in high frequency welding in PVC(Polyvinylchlorde) (something called simply vinyl) and PU(polyurethane) which are the most common thermoplastics that are wieldable by HF. also it is possbile to perform HF welding on other types of materia inculding naylon, PA, ABS, modified TOP, PETG, but particular attention should be pay on working parameters.

HF welding is not suitable for PTFE, polycarbonte, polystyrne, polyethylene or polypropylene. However, a special type of mixed fabrics have been produced recently, which have the capability to be HF welded.The material can be thick or thin, reinforced or coated. It cab also be plain, coloured or structure/patterned.

Normally heat welding has been used as the main technique of joining or welding base materials to top films. It has become more apparent over the last few years that the costs of these specialized films are becoming more and more expensive and also difficult to recycle. Therefore many companies are looking for a solution to this.

- Awning Industry—Hot wedge, hot air, & impulse welders for PVC & acrylic welding of Awnings, shades & marine products!

To produce acrylic and PVC awnings and shades there are three heat sealers from which to choose. We can help you choose or design the right shade sealer equipment for your acrylic welding and PVC welding needs. Choose from any of our awning welding machines and equipment below. Contact us for help choosing the right awning welding machine for your application.

To produce acrylic and PVC awnings and shades there are three heat sealers from which to choose. We can help you choose or design the right shade sealer equipment for your acrylic welding and PVC welding needs. Choose from any of our awning welding machines and equipment below. Contact us for help choosing the right awning welding machine for your application. - Inflatable Industry—Heat-sealing equipment for welding inflatable products!

We manufacture a variety of inflatable welding machine equipment for the production of inflatable products. We will design a machine to fit your specific inflatable production needs.

We manufacture a variety of inflatable welding machine equipment for the production of inflatable products. We will design a machine to fit your specific inflatable production needs. - Packaging Industry—Packaging Systems, welding machines to the Poly-woven Polypropylene bag industry.

We design and build robust dependable packaging industry hot air welders. Our customers span the globe in industries such as agriculture, animal feed, pet food, chemicals, minerals,pharmaceutical, medical, food and building materials. Our machines are recognized for their quality, durability, innovation and value

We design and build robust dependable packaging industry hot air welders. Our customers span the globe in industries such as agriculture, animal feed, pet food, chemicals, minerals,pharmaceutical, medical, food and building materials. Our machines are recognized for their quality, durability, innovation and value

- Install high Q oscillation value in the radio frequency welding machine which is stable and reliable in output.

- Two working positions work alternatively to improve the production

- Pneumatic press system, max pressure can up to 350KG

- With heated electrode welding horn holding plate.

- International standard working frequency 27/12 MHz + -0.6%.

- Anti spark device with 5557,to protect machine and welding mould from over current

- Working voltage can be 1/3 phases, 220V/380V, 50/60Hz + ground or customized

- Electric resistances and temperature control by a thermo regulator.

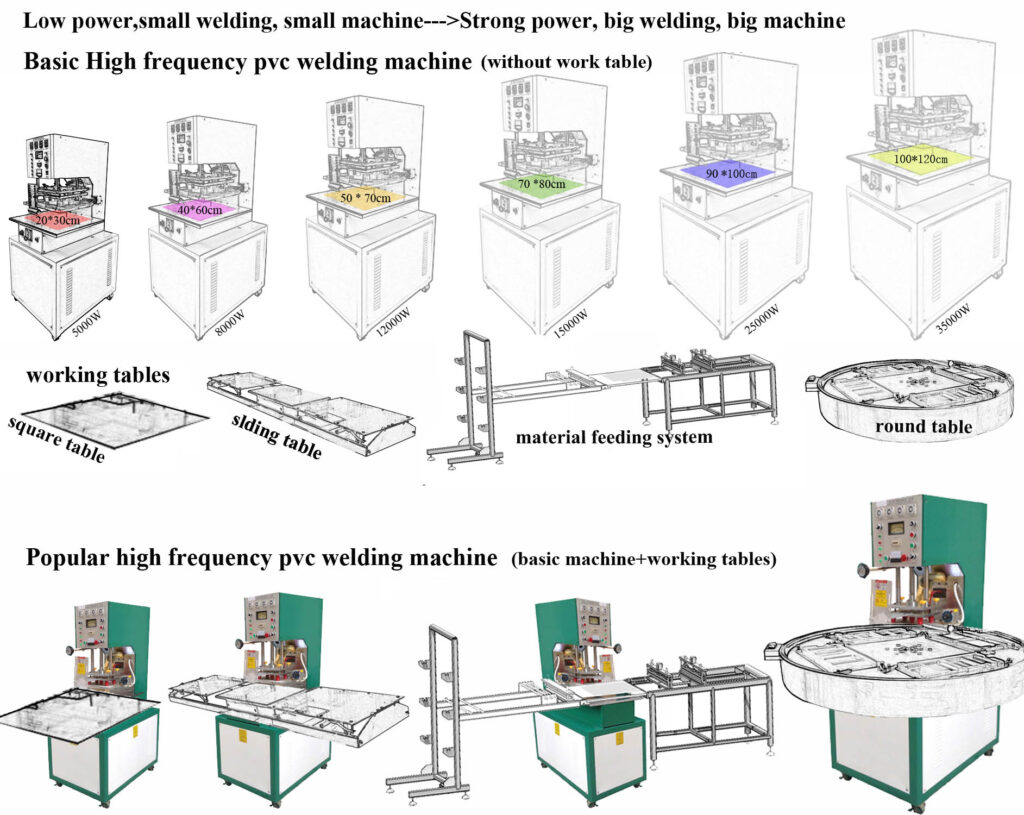

Check this picture, we could see that high frequency pvc welding machine is a single function machine specialized for pvc or pvc compound material welding work. High frequency plastic welding machine mainly consists of two parts:basic major welding body+suitable working positions.

So there are two steps for choosing suitable high frequency pvc welder:

- 1).Suitable welding power. As usual, 1KW high frequency power is ok for welding 20 square cm. If you need to weld 2cm width * 100cm length areas pvc fabric material, we need to choose 10KW high freuqency pvc welder.

- 2). We have 4 major working table designs that can install on the basic high frequency welding machine.(square table, round table, sliding table, material feeding system). The suitable working positions is needed to choose according to welding position and design of products.

We need to make welding mold according clients information in details& samples and drawing. Install the most under the upper electric plate of high frequency pvc welding machine. And then could start welding process.

We have very clear machine operation instruction for each machine that we design and made for our clients.

We also introduce the high frequency pvc welding machine install process in our webage welcome to check: How To Install New High Frequency Welding Machine。

- We need to test and adjust machine well before production. This is the instruction page about how to test your hf machine. Please kindly check: how to test your hf machine;

- And we also introduce the high frequency pvc welding machine operations in our webage welcome to check:How To operate High Frequency Welding Machine。

- Problem:No Working Current

1)Check,Grid Resistance is broken or not.If yes replace gird resistance.

2)Check,Voltage connect wire fall off or not.Check voltage transformer and Check diode broken or not.If yes. Replace it.

3)Check welding horn moving adjustment broken or not.

4)Check Rely KAZ is fall of or not. - Problem:High frequency current goes up automatically quickly after turn on power switch and on-load work. Rotating high frequency current adjustment and make it small.

- Problem:On-load current get bigger when working without products.

1).Inside of generator&electrical box is not clean. Just clean it.

2).Adjustable capacity is spark, polishing the corrosion part.

3).Upper part of welding mold and generator can not contact well. - Copper sheet from generator and adjustable capacitor bad connection

1).Top cover of generator and cavity is not contact well.

2).Capacities next to the high frequency lamp broken.

3).The gate capacitance broken. - Problem:High frequency lamp’s brightness is not enough. Poor contact or tube aging

- Problem:Motor reversal Reverse connection of power supply voltage.

- problem:Pneumatic part is not work.

1)Pneumatic solenoid valve burning.

2)Pneumatic open switch is broken. - Problem:Machine is not work after turn on power switch. Fuse broken and bad connection of supply voltage.

- Every few days in each working place filling the oil, and often wipe clean.

- Every six months in various parts of the machine cleaning and lubrication, removethe transformer high voltage capacitor, cooling fan and the dust of the vibration barrel

- The output capacitor cavity sidecaused light by dust or other object, make the aluminum board face burn out. You should be timely mend the burn surface smooth with a file repair.

- Compressed air water accumulated in the oil-water separator and the main filters,exclusion of water before use of the machine each time, if the lubrication oil in the oily water separator below lines, must be combined with special oil (Oil lubricating oil should be used in corrosion resistance, such as PS – 5)

- High frequency plastic welding machine should be clean up once a month. (Special the dustin oscillators)

- Mold must be kept clean, or it will cause lighter and make the mold damage, such asmold burn out, then use after fixed

- Ground wire of copper often compression, easily damaged must be replaced if thereis any damage

- Insulation material choice: general use insulation cloth, other materials have insulation paper,insulating tape, glass, teflon etc.

other plastic package box making machine

7002.png)