PVC/PET cylinder box machine

high frequency weld machine

other plastic boxes machine

high frequency pvc blister welding machine PVC lip balm care stick toothbrush packaging industry

Brief Introduction

- This is a automatic high frequency pvc blister welding machine with peumatic drive moving control part. There are four working position under the welding heads.

- This kinds of radio frequency welding machine install a finished welded products fetch robot.So it is need two operators to place blister on the positions. It is good for double side blister welding with margin cutting work.

- The popular model is: JC-5000ET-4AC-R1, JC-8000ET-4AC-R1, JC-10000ET-4AC-R1, JC-12000ET-4AC-R1 .

Applications

- We name this machine as high frequency PVC blister paperboard welder

- This is a kinds of expert high frequency pvc blister welding machine for daliy necessarily clamshell lip balm,lip care stick,Lip Moisturize,makeup,AA battery,lipstick and hardware clamshell paperboard packaging. high frequency pvc clam shell welding machine.

- It is also wide used for making handbag, pencil box/id card sleeve ,small spraying toys, leather products, carpet, plastic inflatable products clothes and shoes embossing tool, trademark, box, air tool, carpet, package bag, heat water bag, medical treatment articles, stationary, photo album, physical good, pvc folding box, glass box, garment logo welding and shoe upper and so on.

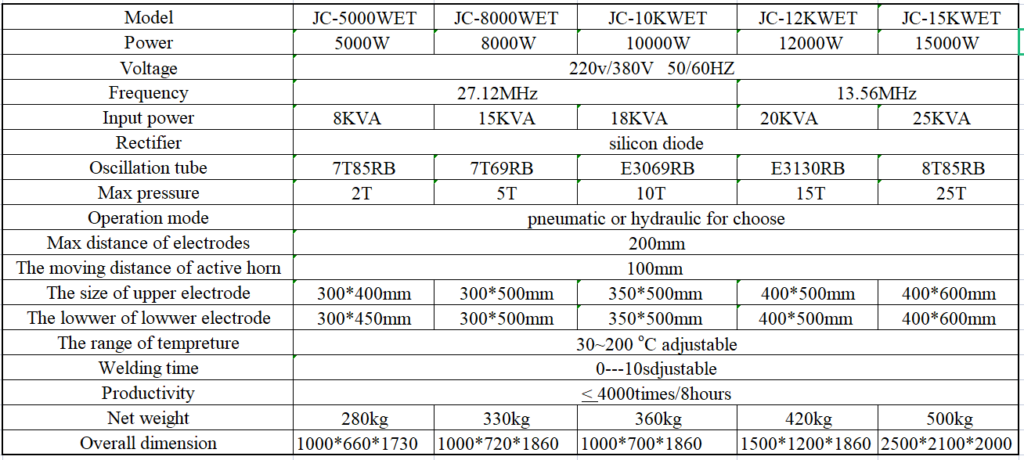

Specifications:

- Using high Q value vibration tube for stable and reliable output

- With round working table which rotate automatically/ by control button

- With 3~6 working positions on the table for choose which work alternatively

- pneumatic pressing system, max pressure can up to 350KG

- Heated electrode welding horn holding plate for good plastic welding result

- HF generator at a stabilized frequency of 27.12MHz. + -0.6%.

- With 5557 anti-spark device, for protecting machine and welding mould from over current

- Feeding voltage 1/3phases,220V/380V, 50/60Hz + ground or customized

- Production speed: 3000~4000 cycles per days( 8 working hours as usual).

- The program is pre-setting up, the circuit can be counter-action of two circuits

- With high precision temperature controlling can assure the coherence of welding

7002.png)